ACME Dynamic Motion Seat Product Line

FIGHTER TYPES

F-16 ACES II

T-6

F-15 ACES II

T-50

M346

T-7

HELICOPTER TYPES

H-60 VARIANTS

EH-101

S-70

S-92

NH90

AH-1Z

UH-72

AH-64

UH-1Y

OTHER VEHICLE TYPES

VMAX

LOCOMOTIVE

Dynamic Motion Seats Overview

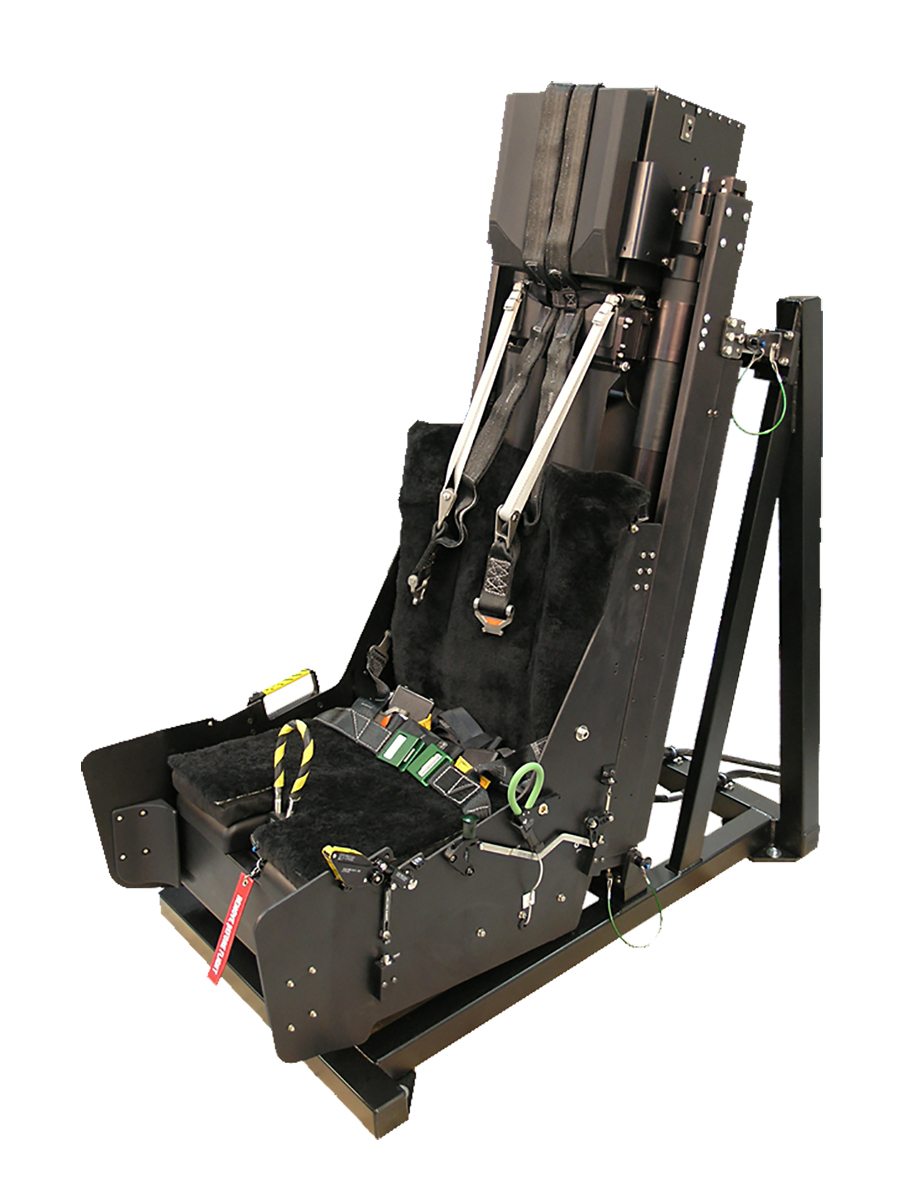

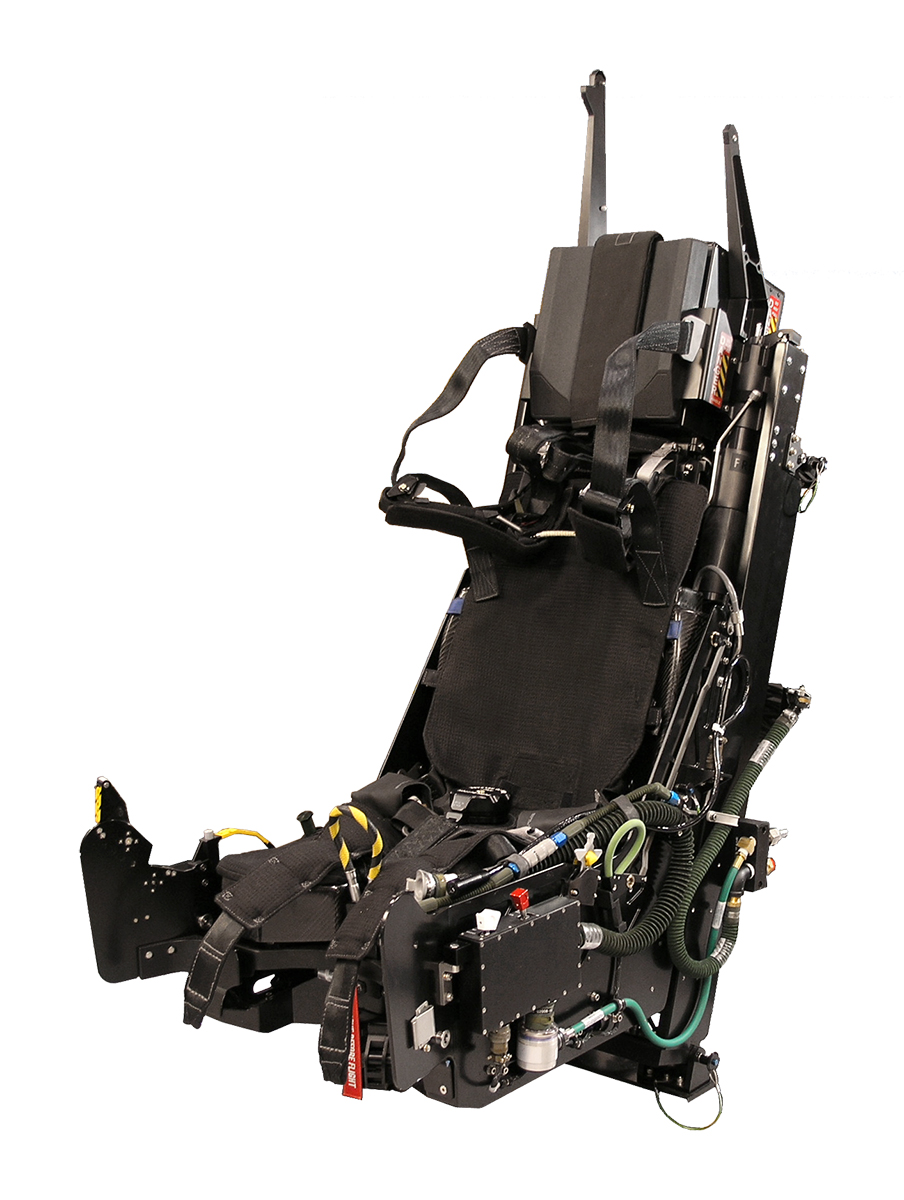

What is a Motion Seat?

A Dynamic Motion Seat (DMS) is a simulator crew seat with the motion components built inside the seat. The DMS provides cueing using simulator model accelerations. The DMS provides cues directly and physically to the crew’s body. The seat uses motion and pressure to create the cues. To simplify: the crew on the seat can feel the flight maneuvers. Crews on the seat feel the in-flight buffets and vibrations.

Why Use a Motion Seat?

Motion seats provide realistic cues. And, motion seats provide benefits not available in other simulator motion cueing systems. For example:

- Motion seats have very fast responses to commands and provide near instantaneous cues. This enables realistic cues for aggressive maneuvers in fighter jet or attack helicopter sims.

- Motion seats can provide both g-onset and sustained g-cues cues. Motion

- Motion seats provide cueing more cost-effectively than traditional motion platforms.

Explore the website! We discuss each of the points in detail and show you the works for your simulator needs. We explain the seat and its deliverables, how it works, and how it compares to other cueing systems. There’s details about the specific seat types for specific aircraft trainers. We explore the life-cycle support and warranty for the seats. The site also explains the benefits for you. We explain special features and even look at some concerns you might have.

How it Works

ACME’s Dynamic Motion Seat systems use individual electric motors inside the seat. The motors move seat plates and the entire seat assembly to apply pressure and motion cues to the crew on the seat. The seat motors are controlled by the electronics that get their commands from the seat computer. The seat computer uses acceleration signals from your simulator. The signals feed over Ethernet into the motion seat computer. The seat computer’s algorithms convert the acceleration signal into motion commands. The seat computer determines which motor(s) in the seat move and how fast and how far. The seat system does all the motion math. No need to be an aerodynamicist or write the software commands to drive ACME’s seat.

Motion Channels

Several motion channels move inside the seat to provide cueing. Sometimes motion channels move alone and sometimes they move in concert. The seat computer determines which motors or channels provide the best cue at any moment.

The many motion channels provide realistic cues in all directions. Motion channels in the seat pan can move left/right or up/down. Channels in the seat back can move in/out or left/right too. Belt or harness channels can tighten or loosen. Motion channels can move the seat itself up or down too.

The motion panels provide a combination of motion and pressure cues to the crew. Motion cues help the crew feel the aircraft movements and pressure cues help simulate the forces felt in flight.

The seat is different than other motion systems. Other systems must return a motor to neutral to make the next cue. It’s known as washing out. But, motion seats can hold pressure to provide sustained cues like G’s or acceleration.

Customers can choose the specific motion channels needed. Or, ACME can provide expert advice before buying. We can suggest channels that provide the best cues for specific maneuvers or events.

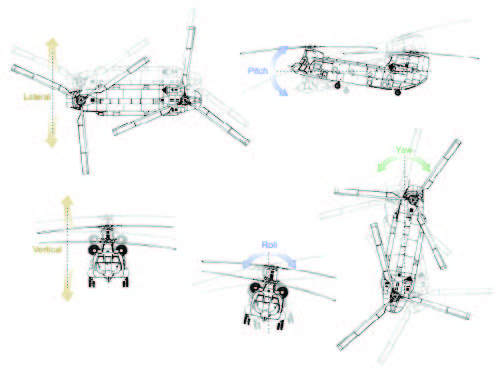

6 Degrees of Freedom (6 DoF)

Motion seats provide cueing in all 6 degrees of freedom through a combination of motion channels working in concert. Multiple channels may be required to provide a specific cue in a given motion degree of freedom. See attached image for reference.

For example,

- To provide cues upward/downward (One degree of freedom) for pure pitch cue, the seat pan and seat bucket move vertically up or down (two motion channels in concert)

- To provide cues in roll (One degree of freedom) the seat pan tilts and the seat back moves laterally (two motion channels in concert)

- To provide cues left/right (One degree of freedom) for a pure yaw cue, the seat back pan moves laterally and as necessary is augmented by the pan tilt (two motion channels in concert)

- To provide fore/aft cues (One degree of freedom) for a pure acceleration/deceleration, the seat back pan surges forward or aft and the seat harness retractor tightens/loosens (two motion channels in concert)

- To provide cues such a pitch acceleration, the seat pan moves vertically, the harness loosens, and the back pan compresses forward (three channels in concert)

At any moment all of the seat channels can be in motion.

General Flight Cues

Dynamic Motion Seats provide cueing. Cueing is not simply motion. Cues provide detailed information beyond simple motion. In many cases simple motion in simulators may be not be enough to provide detailed cueing. Dynamic Motion Seats provide cueing. Cueing is not simply motion. Cues provide detailed information beyond simple motion. In many cases simple motion in simulators may be not be enough to provide detailed cueing.

Most simulator motion consists of an actuator excursion then a slow reset to a neutral position (washout). Washout is intended to be imperceptible. Washout enables the actuator to reset to a position that enables the actuator to provide potentially full excursion for the next maneuver.

Motion platforms stimulate motion onset but don’t provide sustained motion cues. Motion seats can provide pressure as well as motion to provide a complete cue.

Also, the speed of the motion changes is important to cueing. ACME Motion seats excel at very quick, very small motions that are beyond the capability of motion platforms.

Cueing can be a combination of motion, frequency, amplitude, direction, pressure, tension speed, and more. ACME motion seats use all of these elements to create individual, instantly recognizable cues. It’s the recognizable cues that are the key to training.

Once a cue is recognized, specific actions occur in response to the cue. For example, the pilot triggers off a bomb and feels the weapon depart the aircraft. ACME motion seats provide cues AS training.