A Motion Seat by Any Other Name

Motion systems play a vital role in delivering immersive, effective training. From home gaming setups to high-end defense platforms, the use of motion cueing is widespread for one simple reason: it works. These systems simulate the real forces and sensations that...

Enhancing Military Training with ACME Worldwide’s Simulators

ACME Worldwide Enterprises is at the forefront of revolutionizing military training through innovative simulation technologies. Specializing in motion cueing and realistic weapon systems, ACME offers solutions that provide immersive, cost-effective, and safe training...

The Value of a Rare Team: ACME’s Commitment to Customer Service Excellence

In an industry often marked by high turnover and shifting personnel, ACME stands out for our remarkable consistency and long-term dedication to customer success. Since our founding in 1994, ACME has built more than just cutting-edge technology—we have built enduring...

Changes Ahead: Increasing Customer Satisfaction

ACME, long recognized for our exceptional customer service, is taking major strides to make our digital experience as reliable and responsive as our team. In line with our enduring commitment to customer satisfaction, ACME is launching a series of major enhancements...

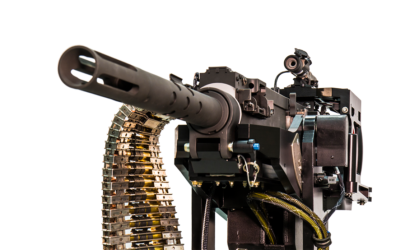

ACME Worldwide Enterprises Realistic Replica Weapon Training Systems for Large Caliber Weapons

ACME Worldwide Enterprises is a recognized leader in the development of advanced replica weapon systems, with specialized expertise in crew-served machine guns of nearly every type and caliber. Our patented full-force recoil system delivers an unparalleled level of...

Mask Air Systems: Essential Aircrew Training Solutions from ACME Worldwide Enterprises

ACME Worldwide Enterprises offers advanced Mask Air Systems designed to provide vital aircrew training in both standard and emergency breathing procedures. Our pneumatic pallet—originally developed to support G-suit systems—also delivers a high-volume, low-pressure...

Advancing Naval Training with Cutting-Edge Replica Weapon Systems

In the dynamic and demanding world of naval operations, the need for realistic and effective training solutions has never been greater. ACME Worldwide Enterprises is at the forefront of innovation, providing state-of-the-art replica weapon systems for sailors and...

ACME Worldwide Enterprises: Delivering Complete Product Support for Long-Term Success

At ACME Worldwide Enterprises, we pride ourselves on delivering more than just cutting-edge products—we provide a comprehensive suite of product support services to ensure our equipment performs reliably and efficiently for years to come. From setup to ongoing...

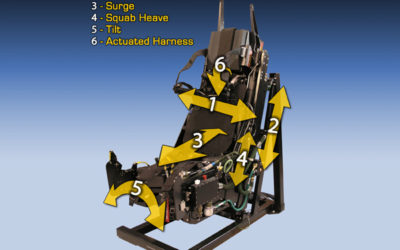

DMS vs. The Little Linear Actuator Platform: Why ACME’s Solution Leads the Way

Motion cueing is at the core of creating realistic training experiences in simulators, but not all systems deliver the same level of immersion. ACME Worldwide Enterprises’ Dynamic Motion Seats (DMS) are redefining the standard for motion cueing, leaving behind the...

Enhance Simulator Training with ACME Worldwide Enterprises’ Static Seats

ACME Worldwide Enterprises continues to push the boundaries of innovation in simulation training with its cutting-edge Static Simulator Seats, designed to meet the diverse needs of military, law enforcement, and commercial training programs. These high-fidelity static...

Press Release: ACME Selected to Provide Replica Weapon Systems for Veraxx Helicopter Simulators

ACME Worldwide Enterprises Inc. is proud to announce that it has been selected by Veraxx to provide replica light machine weapons for new helicopter simulators for a EUCOM FMS customer. This marks the second time ACME has partnered with Veraxx on a weapon training...

Ammunition Canisters, Feed Systems and Feed/Exhaust Chutes Training Elements

Ammunition Canisters, Feed Systems, and Feed/Exhaust Chutes: Key Training Elements for Machine Gun Operators In machine gun training, mastering the art of reloading is a critical skill that directly impacts the success of a mission. ACME Worldwide Enterprises...

The Weapon Mount is Part of the Training

The weapon mount is a critical component of firearms training. The type, features, and capabilities of the mount directly impact the effectiveness of training exercises. ACME Worldwide Enterprises Inc. provides a wide range of options to meet your specific needs,...

Commercial Applications for Our Replica Weapons

ACME is transforming the entertainment industry with our advanced products designed specifically for immersive and thrilling experiences. Designed to meet demanding military needs for fidelity and realism, our cutting-edge products are perfect for immersive...

Looking to the Future: Replica Seats & Weaponry

As technology evolves at a rapid pace, so too does ACME's commitment to pushing the boundaries of simulation and training. With a keen eye on future military developments, ACME is at the forefront of integrating advancements into products. This blog explores ACME's...

ACME’s GTS Transformation to Augmented Reality

In the rapidly evolving world of military training, technology plays a pivotal role in preparing servicemen and women for real-world scenarios. ACME is at the forefront of this transformation, enhancing its Gunnery Training System (GTS) with cutting-edge Augmented...

Transforming Helicopter Rescue Training with ACME’s Advanced Rescue Hoist Simulator

When it comes to aerial rescue operations, precision and reliability are a critical component. The ACME Rescue Hoist Simulator offers a game-changing solution that revolutionizes training protocols for military and commercial helicopter crews, who must perform...

ACME DMS for T-7 Flight Simulators

The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.ACME Worldwide Enterprises, Inc. announces a contract award from Boeing to produce ACME’s True Q® Dynamic Motion Seats (DMS) for the T-7 simulators. The...

DMS for TRU Simulation + Training T-6TH Texan II Simulator for the Royal Thai Air Force

U.S. Air Force photo by Master Sgt. David Richards. Use of DoD Imagery does not imply product endorsement. ACME True Q® Dynamic Motion Seats selected for RTAF Beechcraft T-6TH Texan II Simulator Under a recently awarded subcontract, TRU Simulation + Training, a...

ACME Achieves ISO 9001:2015 Certification

ACME Achieves ISO 9001:2015 Certification ACME Worldwide Achieves Quality Certification under ISO 9001:2015 ACME Worldwide Enterprises, Inc. is proud to announce that in 2021 we have earned ISO 9001:2015 certification with our quality management system. ISO 9001:2015...

ACME’s True Q® Dynamic Motion Seat Facilitates First-of-its-Kind Simulation Application

ACME Worldwide Enterprises, Inc. today announced the use of its True Q® Dynamic Motion Seat to facilitate unprecedented research by the Dynamic Interface Virtual Environment (DIVE) program. DIVE is an ONR funded program, being conducted at NAVAIR, Pax River, aimed at developing an accreditation process by which a Wind Over Deck (WOD) conditions can be modeled based on simulation data.

ACME licensing data from Collins Aerospace

ACME Worldwide Enterprises, Inc. recently signed an agreement with Collins Aerospace to produce replica ACES 5® next-generation ejection seats for military aircraft simulators. Under a licensing agreement with Collins Aerospace, ACME will produce True Q® Dynamic...

Bugeye Technologies – ACME M240

The U.S Army contracted Bugeye Technologies as a part of the Synthetic Training Environment (STE) program to prototype Door Gunner Trainers. This video demonstrates the integration of various product technologies into a virtual reality simulation using ZedaSoft’s CBA®...

See the GTS at the AAAA Summit – Booth 1088 (April 14-16)

GTS: TRAIN EVERYTHING - TRAIN ANYWHEREACME’s Gun Active Recoil (GAR®) Gunnery Training System (GTS) is complete helicopter gunnery Training. Turn-Key system includes everything needed for realistic, out-the-window helicopter gunnery training. Look out and down from...

True Q® DMS Headed To Argentina

ACME Worldwide Enterprises, Inc. was recently selected to provide True Q® Dynamic Motion Seats to TRU Simulation + Training, a Textron Inc. (NYSE: TXT) company, for their T-6 aircraft operational flight trainer, which is expected to be provided to the Argentina Air...

I/ITSEC 2018

Naval Shipboard Gunnery TrainingTrue Q Dynamic Motion Seats (DMS)The Navy was demonstrating their Shipboard Gunnery Training System at I/ITSEC 2018 that includes ACME’s M2 with Gun Active Recoil, Replica Weapon System.True Q Dynamic Motion Seats (DMS) in action at...

The latest S-70 True Q® Dynamic Motion Seat (DMS)

ACME Dynamic Motion SeatsThe ACME S-70 Dynamic Motion SeatThe S-70 is a versatile, medium-size, twin-engine helicopter built by the Sikorsky Aircraft company and used for commercial and military aviation program worldwide. The S-70 is a transport helicopter providing...

Press Release – TrueQ® DMS for Yankee & Zulu Simulators

ACME’s TrueQ® Dynamic Motion Seats for Yankee & Zulu Simulators ACME Worldwide Enterprises, Inc. (ACME) has been chosen to provide TrueQ® Dynamic Motion Seats for the USMC UH-1Y and AH-1Z simulators under the H-1 Lot VI New Devices and Technical Refresh program....

Gunnery Training System (GTS) at the SHOT Show 2019

The Gunnery Training System (GTS) was the talk of the SHOT Show 2019 in Las Vegas. We had a great turn out, check out the links below to see what everyone is saying! https://youtu.be/PMJpHbpi5Gs...

The Gunnery Training System (GTS)

GTS: TRAIN EVERYTHING - TRAIN ANYWHERE ACME’s Gun Active Recoil (GAR®) Gunnery Training System (GTS) is complete helicopter gunnery Training. Turn-Key system includes everything needed for realistic, out-the-window helicopter gunnery training. Look out and down from...

Press Release – ACME’s New Patent #10001338

New Patent #10001338 ACME Worldwide Enterprises, Inc. New Patent #10001338 ACME Worldwide Enterprises, Inc. earned a new patent for the all-electric, Gun Active Recoil (GAR®) system for machine gun simulators. The new patent, #10001338,...

Press Release – ACME’s Tactile Technologies for Royal Navy Mk4 Helicopter Trainers

ACME’s Tactile Technologies for Royal Navy Mk4 Helicopter Trainers ACME’s Tactile Technologies for Royal Navy Mk4 Helicopter Trainers ACME Worldwide Enterprises, Inc. recently delivered replica weapons, a rescue hoist simulator, and Dynamic...

Press Release – G-suit Systems for Lockheed Martin

G-suit Systems for Lockheed Martin G-suit Systems for Lockheed Martin ACME Worldwide recently completed a set of two G-suit Systems for F-16 simulators under subcontract to Lockheed Martin Rotary and Mission Systems. The advanced G-Suit systems...

Press Release – Marine Common Aircrew Trainers (MCATs)

Marine Common Aircrew Trainers (MCATs) Marine Common Aircrew Trainers (MCATs) ACME Worldwide Enterprises, Inc. (ACME) has been selected by Kratos Defense & Security Solutions, Inc. (Nasdaq: KTOS), to provide replica weapon systems for the US...

Annual Navy Technology Exercise

ACME’s team participated in the 2017 Annual Navy Technology Exercise (ANTX) in Dahlgren, Virginia in September. We brought our M2, .50 Caliber replica machine gun system as part of the FAC/FIAC Integrated training system. At ANTX, Navy personnel were able...

Guns Galore at ACME!

It’s a busy Autumn at ACME where we have dozens of replica weapon systems in work right now. Our highbay is full of different weapons for many customers and many programs. There’s replica weapons completely across the shop. A quick glance shows GAU-21’s,...

U.S. Secretary of Education Tries a ACME Dynamic Motion Seat

Under an ongoing Cooperative Research and Development Agreement (CRADA), ACME Worldwide Enterprises has loaned a Dynamic Motion Seat system to the US Air Force Academy for evaluation and research by cadets. The cadets, led by Dr. Victor Finomore,...

I/ITSEC 2017 Booth 1159

On Display at I/ITSEC 2017 - ACME Booth #1159 - M-2 Gun Force Simulator & Dynamic Motion Seats ACME Worldwide’s M-2 Gun Force Simulator with full force Gun Active Recoil (GAR®) system will be on display. On Display at I/ITSEC 2017 - ACME Booth #1159 - Fighter and...

Kratos Training Solutions

ACME Worldwide Enterprises, Inc. has been selected by Kratos Training Solutions to provide a suite of replica weapon systems for the US Navy MH-60 Naval Aircrew Training Systems (NATs) and four MH-60S Aircrew Virtual Environment Trainer (AVET) trainers being produced...

Windloading Force

Remember riding in a car when you were a kid and you would put your hand out the window? You could hold your hand flat and zoom your arm up and down like an airplane. Or you might hold your hand flat against the wind, relax your arm and just let the air blow your arm...

Small Footprint Simulators

When many people think of a military flight simulators they envision the bulbous enclosure on the gigantic hydraulic legs. Sure, motion platforms are one type of flight simulator. But, there’s a vast range of trainers that are not that complex and not that expensive....

Machine Gun Malfunctions

Machine guns are wonders of engineering. They handle hundred of rounds per minute and thousands of rounds over a lifetime. They deal with the massive heat and gas pressure as the rounds fire. And, they operate in the toughest environments and can be exposed to shock,...

G-Suit Systems

Fighter jets operate in a dynamic world of banks, climbs, dives, rolls, vibrations, shudders. The jet continuously changes accelerations and G-forces. G-loads are an inseparable part of the fighter environment. Pilots use the cues from the motion, pressure, and...

Ejection Seat Trainer

ACME’s Dynamic Motion Seats are the perfect way to add motion cues to fighter cockpit trainers. Customers can answer other training needs with the seats too. True Q® seats are great trainers for ingress/egress and ejection training. The key is the realism of the...

Why Demand Realistic Recoil?

Pull the trigger on any firearm and you will immediately understand Newton’s law about equal and opposite reactions. Recoil is an inseparable part of shooting. It instantly affects how you engage the target. And the effects are amplified for machine guns. Each machine...

ON DISPLAY I/ITSEC 2016 ACME Booths 660 & 665

On Display at I/ITSEC 2016 - ACME Booths 660 & 665 - M-2HB .50 Caliber Gun Simulator ACME Worldwide’s (www.acme-worldwide.com) M-2HB .50 caliber machine gun simulator with full force Gun Active Recoil (GAR®) system will be on display as part of Operation Blended...

Operation Blended Warrior – ACME 2016

ACME Participating in Operation Blended Warrior 2016 The National Training & Simulation Association (NTSA) is serving as the sponsor for a Live-Virtual-Constructive (LVC) special event otherwise known as Operation Blended Warrior (OBW) that is being planned for...

By the Numbers-Dynamic Motion Seats

Proven Products, Ready Now Prototypes (or new production designs) begin at step one. Design Step 1 is also Cost Step 1 and there’s lots more potential cost steps ahead on the production highway. Even for the highest quality products, new designs often need refinement...

ACME @ ITEC 2016

Hello Europe! The customer is king! ACME believes business should come to the customer and learn about your needs. Listening and understanding your requirements first is key. So, we’re at the ITEC simulation show in London to talk with our European customers. We look...

FIST2FAC: Future of Navy Combat Training?

For Immediate Release: April 11, 2016 By Warren Duffie, Office of Naval Research ARLINGTON, Va.—Lookouts on the bridge of the USS Michael Murphy (DDG-112) scanned the surrounding ocean. All seemed well—clear skies, peaceful waters, busy merchant ship traffic....